| Specializing in the production of Silicone,Rubber & Plastic devices |

|

|

|

|

|

|

|

|

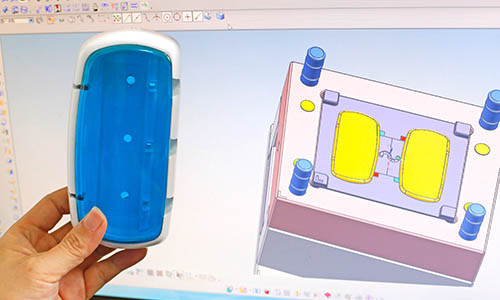

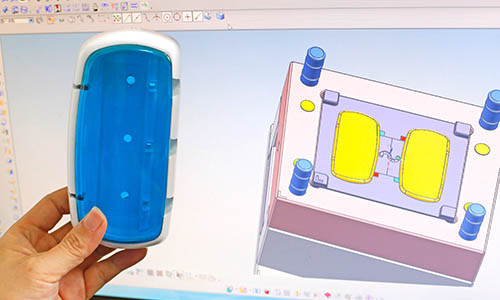

Mold Design & Manufacturing |

|

|

|

|

SENTUO Rubber & Plastic tooling workshop has above 15 years’ experiences and technology on mold design and fabrication for custom rubber parts and custom plastic parts, specialize in compression mold, transfer mold and injection mold, we know how to design the mold structure to succeed in implement smooth production and optimal cost-efficiency.

SENTUO Rubber & Plastic is equipped with precise CNC, EDM, engraving and milling machines, not only make molds for our internal rubber parts and plastic parts production, but also make molds for rubber and plastic industries all around the world.. |

|

|

| |

Excellent Mold Design Ability |

|

|

| |

|

|

Mold design team is the key of SENTUO Rubber & Plastic technology, all of the molds of rubber parts or plastic parts are programed and designed by mold design team, we can help you solve a variety of problems of the molds if you bring us the rubber or plastic projects.

The points of mold design:

|

| 1. |

|

Optimum mold structure to realize high-efficiency production. |

| 2. |

|

Obey the requirements of the drawing, strict tolerance control. |

| 3. |

|

No flash-line on the important surfaces of rubber parts or plastic parts. |

| 4. |

|

Mold cost and mold life. |

|

|

|

|

| |

Outstanding Processing Technology |

|

|

| |

SENTUO Rubber & Plastic skillful technicians have outstanding technology of mold fabrication and earnest dedicated attitude, that is why we keep excellence on custom rubber products and custom plastic products manufacturing field.

Most of the technicians and workers serve in SENTUO Rubber & Plastic for many years and have rich experiences in mold fabrication, we care for all small details on processing, to ensure produce high precise and long-life molds for rubber or plastic products manufacturing. |

|

|

|

|

|

|

|

|

| |

Excellent Mold Assembly Ability |

|

|

| |

|

|

Mold assembly of rubber or plastic parts is a highly specialized technique, our workers with experience, technique and diligent attitude could fully consider the parts’ tolerance to adjust, modify, calibrate step by step in the mold assembly process until all components of the molds optimum match. |

|

|

| |

Completed Mold Manufacturing Flow Chart |

|

|

|

|

|

|

|

|

| Rubber & Plastic Products Manufacturer , Specializing in Custom-made. |

|

|

|

|