| Specializing in the production of Silicone,Rubber & Plastic devices |

|

|

|

|

|

|

|

|

Plastic Parts Manufacturing |

|

|

|

|

SETNUO Rubber & Plastic is also a professional and technical custom plastic products injection molding company, equipped with advanced injection molding machines including two shot injection machines, produce all kinds of custom plastic enclosures, custom plastic gears and custom plastic parts, all of processes in-house from mold design, mold fabrication and plastic injection molding to quality control, to assure to produce high-precision products for our customers.

We use our outstanding plastic parts injection molding abilities and mechanical technology to assist our customers to solve all kinds of design and custom plastic injection molding problems, especially good at molding complex plastic parts and welcome small quantity custom projects. |

|

|

| |

High Precision

Injection Molding |

|

|

| |

|

|

SENTUO Rubber & Plastic injection molding workshop has state-of-the-art plastic injection machines, self-made molds, experienced technicians of plastic parts manufacturing, completed quality control system and skillful QC workers, all of them are indispensable and work together, to insure supply high precise and no defect plastic products to our customers. |

|

|

| |

Two Shot Injection Molding |

|

|

| |

SENTUO Rubber& Plastic owns two shot plastic injection molding machines and skillful plastic injection molding processing ability.

Two shot plastic injection molding is the ability to produce complex plastic moldings from two different polymers or two colors at the same time during one machine cycle. Improve bonding quality of the plastic products, reduce cycle times, keep high level of accuracy and high level of repeatability, it is very suitable for complicated plastic parts with two colors or two polymers. |

|

| |

|

|

|

|

| |

PEEK Parts Injection Molding |

|

|

|

|

|

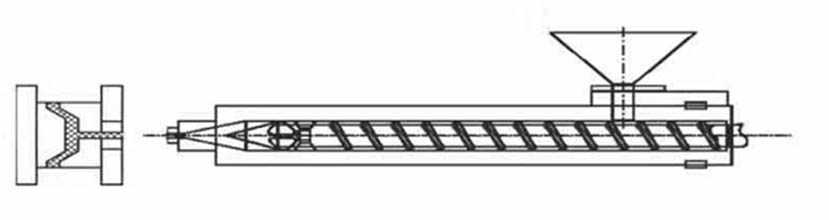

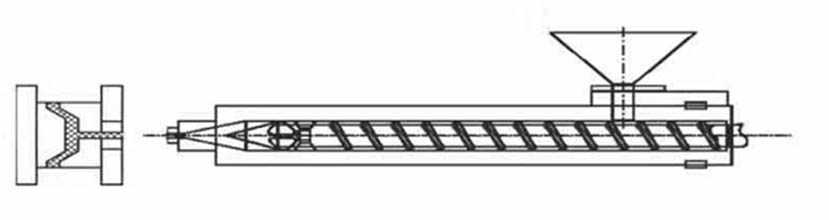

| The parameter of PEEK injection molding |

|

|

| Mold Temperature |

Injection nozzle temperature |

Metering temperature |

Compression interval temperature |

Polymer entry temperature |

|

|

| 150-170-200℃ |

370~390℃ |

365~385℃ |

360~380℃ |

355~375℃ |

|

|

|

|

|

|

|

|

|

|

| Rubber & Plastic Products Manufacturer , Specializing in Custom-made. |

|

|

|

|